Today we will be reviewing 7 important steps when building a concrete pad for your metal building, carport, or garage. These steps are followed as a preliminary guide but are not to be construed as the final authority. The construction trade changes and evolves on a daily basis and there maybe be a more advanced technique for today which was current and effective yesterday. So please speak with your representative at Gatorback Carports before you implement any of these procedures in your construction work. For example, some of our plants and plant managers do not want to use the brick ledge technique described in this and other articles but there are in some regions those who want it used. Some use different wording which could be confusing so please contact us.

First the concrete Pad Length should be 1′ (foot) less than the roof length of the Metal Garage because there is a 6” (inches) overhang on the front and rear of the gable roof line totaling 1’ (foot) longer on the roof than the actual foot print of the building on the ground.

There are two measurements for the length of a building and only the frame length and frame width is to be considered when determining the pad size. The frame length and width is measured from outside corner post to outside corner post. This ground foot print of the building is the frame length and width and is the exact length and width of your concrete pad.

The roof length is one foot longer than the foot print (length on the ground) of the building because of a 6″ over hang on the gable ends (width) of the building. The length of the pad is always one foot shorter than the length of the roof. If you measure the roof from gable end to gable end it is one foot in total longer than the actual ground foot print. Therefore if your roof length is 41′ then your pad will be 40′. The roof length is not the the measurement needed for the concrete pad. The foot print of the building is the measurement needed.

Please contact customer service agent for more information to ensure your proper pad size.

32′ wide (Gable End) by 41 Long Roof Line will be a 40 Long foot print from Corner post (vertical leg) to Corner post

Exception for the concrete pad length being one foot shorter than the roof length is for the state of California where the vertical roof building is not a foot longer because of the gables than the actual foot print. Please contact customer service agent for more information. If you have any questions please contact one of our customer service agents, or ask for a project manager and they will be happy to assist you.

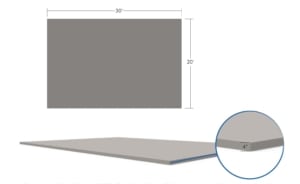

For example, a 20 wide by 31 long building will have a ground footprint of 20 by 30. So the concrete pad should measure 20 by 30 as seen below:

- It is necessary for the side panels, and end panels of the walls of the garage to go over the edges of the concrete pad, otherwise you can not stop water intrusion. Therefore the width of the pad must be the exact width of the garage or metal building. The bottom horizontal base runner will be installed on the edge of the concrete, and the wall panels will go over the sides of the horizontal base runner, and over the sides of the concrete pad.

- The brick ledge is optional and you may choose to not utilize this part of the concrete pad process, but it is recommended for some installations. It provides a cleaner installation as the horizontal base runner will set inside the ledge. It also aids in stopping water intrusion as water seeking entry would hit the side of the ledge and disperse outside the building. But it does take a little extra time and cost; you may simple choose to skip this process and your building will be just as structural sound.

- It begins by building a ledge (Brick Ledge) around the perimeter of the concrete pad for a garage or metal building but this is not necessary for a carport. This brick ledge is made on all four sides of the building. It is not utilized at the garage door openings but it is used on the walk in doors. The base rail which sets inside the brick ledge is used as a door stop on the walk- in doors.

- Some garage owners will not utilize this advantage which aids in keeping water from entering the building because of the extra work, even though it is an advantage by stopping water intrusion if the ground is raised, pad built at proper height and ditches (ways for water to exist away from the building) made then the non brick ledge pad will preform just as properly.

The bottom base plate ( or horizontal frame tubing) runs on top of the concrete pad. This framing tube attaches to the vertical studs. It is the horizontal base tube sets inside the brick ledge. It is the brick ledge that prevents water intrusion.

Pictured above is a RV Cover horizontal base runner and legs that are doubled. This is the same framing used in our commercial buildings (metal buildings over 32 feet wide). Most of our other metal garages use single leg systems, but if you have a double leg then your brick ledge will be 2 1/2 inches x 2 for 14 Gauge = 5 inches. If you order 12 Gauge Framing for the horizontal base runner it is 2 1/4″ wide and will have a brick ledge of 4 1/2 inches wide. Make sure your order states, “12 Gauge Framing on the base runner” if you building is design for that.

Optional Brick Ledge installation:

Now that you’ve determined the proper size of your concrete pad, the next step is to determine if your building needs a brick ledge in the concrete pad. You may choose to skip the optional brick ledge and have the horizontal base runners attach directly to the top of the concrete pad.

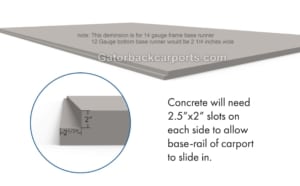

The brick ledge is built around the perimeter of your concrete pad. If you purchase 14 gauge framing material then the ledge will be 2 1/2″ wide by 2 1/4″ deep because the horizontal base runner which is 2 1/2″ square will set inside the brick ledge to prevent water intrusion.

- Gauge of Your Framing Material

If you requested 12 gauge framing material, and you want 12 gauge framing material on your horizontal base runner which runs along the ground the length of your building then you must make an special request for it also which we will notate on the order. 12 gauge framing material is thicker and stronger, but it is only 2 1/4 inches square instead of 2 1/2 inches square on 14 gauge framing. Therefore your brick ledge would be 2 1/4 inches wide by 2 inches tall.

Metal Barns: If you are building a concrete pad for a metal barn and choose the brick ledge option then you will not only have a ledge built around the perimeter of the concrete pad but there will be two other ledges built for the side legs of the center section of the barn. Because of the extra labor in forming the two center ledges for the main building customers often forego utilizing the brick ledge pattern for a metal barn and often build a conventional pad without a brick ledge.

On metal barns customers also frequently have us build a frame out which consist of cutting out the horizontal base rail and legs at a length of 15 feet maximum so that they may move equipment, tractors, autos between the sections without the rail imposing their movement. Removal of this section of the framing does not lessen the structural integrity of the design of the building because the area is reinforced by adding a welded header to the section that was removed.

Garage Door Openings:

- The brick ledge will not be built at the garage door openings, and at this point the bottom horizontal base runner will be removed. Therefore if your garage door is eight foot wide then the brick ledge would not be built for that eight feet.

7. Walk-in Doors: The brick ledge will remain at all walk in doors, and will not be removed from construction. It is the horizontal base runner that the walk in door rest against when shut.

7. Walk-in Doors: The brick ledge will remain at all walk in doors, and will not be removed from construction. It is the horizontal base runner that the walk in door rest against when shut.

We seek to assist you in making sure you building is of the highest quality design and installation. We are offering free drawings for our buildings when generic drawings from our architect will meet the qualifications in your state. Please give us a call for more information. Free drawings are not available for the state of California, and parts of Arizona, and Nevada. Specific Job site drawings, and wet sealed drawings are also extra.

The Gatorback Carports team

Please see the next article on “How to Determine Concrete Pad Size”