Checklist for Metal building Concrete Pad and ground:

1. Carefully consider the location of the installation:

Make sure that the locations and sizes of all existing structures (especially consider any covered decks & porches) will fit with your proposed new building and your entrance and exits to and from the building provide ample room for vehicles.

2 Be sure to check locations of overhead electrical and phone lines and underground gas lines. Mark all utility lines. You may call 811 and they will come and mark your lines for free.

3 Preparing the construction site:

The install site needs to be as level as possible. If you are installing on the ground an unlevel service may vary up to but no more than 3 inches from side to side and front to rear.

4 If your site is more than 3 inches off from being level we may be unable to perform the job, or there may be a charge for extra labor which involves cutting the vertical legs to accommodate for an uneven surface.

5 Make sure your surface is perfectly level at doors, and garage door openings to ensure a solid closure of the door. This will stop partial door closures or cracks in the openings which could allow weather, insects, debris, or even small animals to gain access to your building.

5 Don’t forget the paper work:

Will you need any building permits? We provide generic blue prints for your metal garage or building for free unless your state and city requires site specific drawings or wet sealed drawings, and we can also help you with design work. The state of California along with some other states require site specific drawings. We have a portfolio of building designs which our architects have created, and they are ready to assist with any designs you may need for your carport, garage, or metal building pad construction.

You can avoid costly architectural designs by working with our staff. Our buildings always include free drawings.

6 Delivery of your building:

Our crew will deliver your building on a 30’ long trailer pulled by a dually truck, and they will need to have direct access to the building site. If your location is off the road and wet, or on a steep hill, in a field we may not be able to gain access to the site.

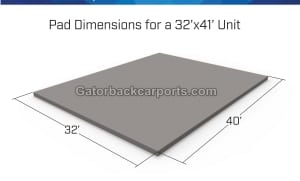

7 Concrete pad Size:

There are two measurements for the length of a building and only the frame length and frame width is to be considered when determining the pad size. The frame length and width is measured from outside corner post to outside corner post. This ground foot print of the building is the frame length and width (gable end) and is the exact length and width of your concrete pad.

The roof length is one foot longer than the foot print (length on the ground) of the building because of a 6″ over hang on the gable ends (width) of the building. The length of the pad is always one foot shorter than the length of the roof. If you measure the roof from gable end to gable end it is one foot in total longer than the actual ground foot print. Therefore if your roof length is 41′ then your pad will be 40′. The roof length is not the the measurement needed for the concrete pad. The foot print of the building is the measurement needed.

Please contact customer service agent for more information to ensure your proper pad size.

32′ wide (Gable End) by 41 Long Roof Line will be a 40 Long foot print from Corner post (vertical leg) to Corner post

The width of the concrete pad is the actual width of the size of the building.

Therefore if the building you purchase is 32 feet wide (on the gable ends) then the width of the pad is 32 feet wide.

Please visit this link for more information on concrete pads:

Please see the next article for concrete pad sizes and design ” Steps for Sucessful Concrete Pad Construction”